Installation Guide of Steel Tank

Basic information of steel storage tank

Function of steel storage tank

The steel sealed vessel, that is steel oil tank, is used for storage liquid and gas. The steel oil tank is the infrastructure in gasoline industry, chemical industry, grain and oil industry, food industry, fire fighting industry, transportation industry, metallurgy industry, national defence industry and so on. The steel oil tank plays an important role in people’s life and the national economic development. It is a special equipment for storage various liquid (or gas) raw material and product. Many enterprises can not produce normally if there is no storage tank. Especially for national strategic material reserves, various storage tanks are necessary. The oil storage facilities in our country are most ground storage tanks which are made by metal. Our website will introduce some basic information about the storage tank with arch roof, storage tank with inner floating roof and horizontal storage tank.Classification of steel storage tank

For different medium, the types of storage tanks are also different. According to the position, there are ground storage tank, underground storage tank, half underground storage tank, marine tank, seabed tank and so on. According to oils, there are crude oil tank, fuel oil tank, lubricating oil tank,edible oil tank, fire water tank and so on. According to the purpose, there are production oil tank, storage oil tank and so on. According to type, there are vertical storage tank, horizontal storage tank and so on. According to structure, there are storage tank with fixed roof, storage tank with floating roof, spherical tank and so on. According to capacity, there are large storage tank(such as vertical tank), the capacity of which is above 100m3 and small storage tank (such as horizontal tank), the capacity of which is under 100m3.Standard of steel storage tank

The common standards of oil storage tank: 1. API650; 2. BS2654; 3. JISB8501; 4.DIN4119; 5. SYJ1016-82; 6. SH3046-92.The material of steel storage tank

The materials of storage tank are tank materials and accessories materials. The tank material can be divided into low strength steel and high strength steel according to tensile yield strength(бs) or standard tensile strength(бb). The high strength steel is used for above 5000m 3 oil tank. The carbon steel is used for accessories, including wind ring beam, fore shaft, spiral staircase, rail and so on.The types of steel for oil tank are 20R 、16Mn 、 16MnR and Q235、 Q345、A36.The structure of storage tank

There are three types of storage tanks which are very popular and most mature in our country: storage tank with arch roof, storage tank with floating roof and horizontalstorage tank.

Structure of steel tank with dome

The storage tank with arch roof is a kind of steel vessel, the roof of which is ball coronary, the tank of which is columniform. The manufacture of storage tank with arch roof is very simple and the cost of construction is very cheap. So it is very popular in many industries in China. The volume of commonly used is 1000 -10000m3. At present, The maximum volume of storage tank with arch roof in China has reaches 30000m3. The bottom of tank is assembled by steel plates. The steel plate of the center of bottom is center plate and peripheral steel plate is margin plate. The margin plate is strip plate or cambered plate. When the inner diameter is less than 16.5m, strip plate is used as margin plate. When the inner diameter is 16.5m or more, cambered plate is used as margin plate. Tank shell is butt welded by many round steel plates. There are two types: sleeve and linear. Overlap joint will be used for circumferential seam on the sleeve shell of tank and butt joint will be used for vertical seam. The storage tank with arch roof is always adopt this ways which is good for assembling of round shell plates.

Butt welding will be used for circumferential seam on the linear shell of tank. The advantage is the diameter of whole shell of tank will be same. It is used for storage tank with inner floating roof.

Technical specifications of steel tank with dome

| capacity(m³) | nominal capacity | 100 | 300 | 400 | 500 | 700 | 1,000 | 2,000 | 3,000 | 5,000 | 10,000 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| dsign capacity | 110 | 330 | 440 | 550 | 770 | 1,100 | 2,200 | 3,300 | 5,500 | 10,700 | |

| dimension of rank (mm) | D1 | 5,172 | 7,750 | 8,828 | 8,983 | 10,263 | 11,580 | 15,781 | 18,992 | 23,760 | 31,852 |

| D2 | 5,252 | 7,830 | 8,368 | 9,063 | 10,343 | 11,680 | 15,818 | 19,092 | 23,808 | 31,402 | |

| H | 5,300 | 7,707 | 8,240 | 8,810 | 9,140 | 10,580 | 11,370 | 11,760 | 12,530 | 14,070 | |

| H1 | 5,870 | 7,920 | 9,148 | 9,194 | 10,533 | 11,847 | 13,110 | 13,857 | 15,143 | 17,504 |

Note 1 : D 1 indicate inner diameter; D 2 bottom diameter; H height; H 1 total height。

Note 2 :The data in the table can be refered. To quote and construct according to drawings.

Structure of floating roof tank

Floating roof tank is composed of a floating in the medium on the surface of the floating roof and vertical cylindrical tank wall. Floating roof tank reserves with medium increases or decreases lift, a ring seal between the floating roof edge and the tank wall, the medium in the tank is always internal floating roof cover, reduce medium volatile. The bottom of the tank: volume of floating roof tank is large, the floor with arched edge plate. The tank wall: the linear tank wall, butt weld should be polished smooth, ensure the inner surface roughness. Floating roof tank is open, for increasing the wall stiffness, should according to the local wind load size, the tank wall top set the wind beam and reinforcing ring. Floating roof: floating roof is divided into single deck floating roof, double deck floating roof and float type floating roof form. Single deck floating roof: consists of several separate compartments to form an annular floating ring, the inside is a single plate roof. Single disc is provided with a plurality of annular steel roof bottom reinforcement. Its advantages are low cost, good repair. Double deck floating roof: composed of upper plate, lower plate and the edge plate, the radial baffle and the baffle into several independent annular tank. Its advantages are large buoyancy, good drainage effect.

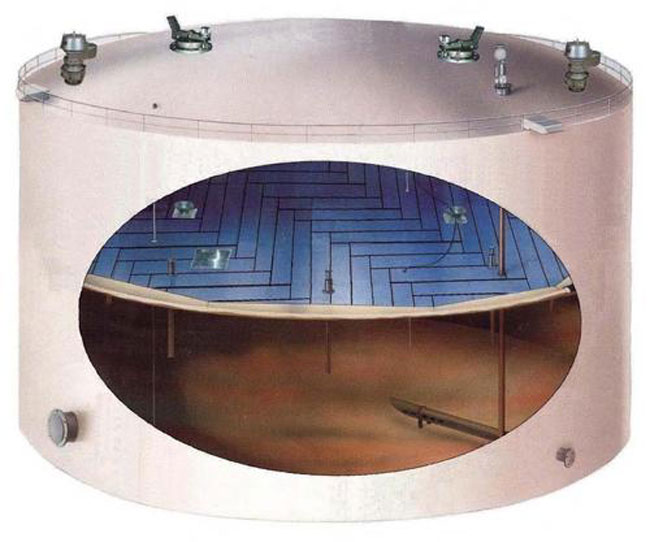

Structure of the inner floating roof tank

Inner floating roof tank is in the dome tank with floating roof and tank, additional floating roof can reduce the volatilization loss medium, outside the vault can also prevent rain, snow and dust from entering the tank, ensure the medium tank clean. This tank is mainly used for storage of light oils, such as gasoline, aviation kerosene. The straight wall of inner floating roof tank, wall plate butt welding system, according to the requirements of the production of vault vaulted tank. The inner floating domestic top two structures: one is the steel floating and floating roof tank top; another is the shape of the aluminum floating roof assembly.

Technical parameters of tank with inner floating roof

| capacity(m³) | nominal capacity | 100 | 300 | 400 | 500 | 700 | 1,000 | 2,000 | 3,000 | 5,000 | 10,000 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| design capacity | 114 | 325 | 430 | 533 | 750 | 1,152 | 2,255 | 3,457 | 5,275 | 10,755 | |

| dimension of rank (mm) | D1 | 4,700 | 6,500 | 7,500 | 8,200 | 9,200 | 11,000 | 14,500 | 17,000 | 21,000 | 30,000 |

| H | 7,050 | 10,300 | 10,300 | 10,660 | 11,840 | 12,690 | 14,270 | 15,850 | 15,850 | 15,850 | |

| h | 408 | 713 | 822 | 893 | 1,007 | 1,199 | 1,500 | 1,863 | 2,300 | 3,284 | |

| H1 | 7,462 | 11,017 | 11,126 | 11,563 | 12,852 | 13,894 | 15,866 | 17,710 | 18,156 | 19,142 |

The foundation of steel tank

Type of foundation

There are usually protection foundation, ring wall foundation and the outer ring wall foundation.

Bearing capacity of foundation

Requirement of bearing capacity of foundation:

| nominal capacity (m³) | 100 | 200 | 300 | 400 | 500 | 700 | 1,000 | 2,000 | 3,000 | 5,000 | 10,000 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| bearing capacity of foundation (t/㎡) | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 13 | 13 | 16 | 18 |

Selection of tank foundation

When the local soil can meet the design value of bearing capacity and settlement requirements and the site is not restricted, it should adopt the protection or the outer ring wall foundation;When the local soil can not meet therequirements, design value of bearing capacity and settlement does not exceed the allowable value, it should adopt the ring wall or the outer ring wall foundation;When the local soil is soft , the outer ring wall foundation can be used after soil foundation treatment;When the field is limited, the ring wall foundation can be adopted.

The construction of steel tank foundation

- The excavation of foundation pit and punning;

- Reinforced concrete and masonry: (omitted);

- Earthwork backfilling and compaction of backfill soil,: more than 500mm;

- Sand cushion: choose, coarse sand, laying 200~ thickness 250mm, slab oscillator watering ramming;

- Asphalt sand cushion: choose, coarse sand and No. 60 road asphalt heated asphalt sand, hierarchical blockpaved, its thickness is 80~ 100mm, the top surface of tank foundation from the center to the periphery of thegradient of 15~35;

- Slope protection construction: after the tank pressure test for slope protection construction, slope and width of 800~ 1000mm. Between the bank and the tank bottom with asphalt mastic packing.

- Storage tank foundation design and construction process please see SH/T3083-1997 "petrochemical steelstorage tank foundation treatment technology specification" and "SH3086-1995 petrochemical steel storage tankfoundation design specification".

Storage tank fabrication and installation

Storage tank construction process is divided into semi precast and on-site installation of two parts.

Semi finished products: the bottom of the tank, the tank wall prefabricated, tank top and other components areprefabricated (concrete precast Fang Falve).

On the spot installation method: divided into flip chip construction technology, construction technology andspecial formal construction technology.

Tank accessories

The winding staircase (or straight ladder): with the rest platform, the width is 650mm, counterclockwise rotation.The tank top is provided with an anti slip steps.

Barrier: the height of 800~ 1000mm.

Bridge: used for tank connection, the width is 650mm.

Manhole: commonly used are available in three sizes: DN500, DN600, DN750.

Light hole: common specifications: DN500.

Cleaning holes or discharge hole: sewage with light oil heavy oil by hole, hole cleaning. There are DN50, DN80,DN100 three models.

Oil hole: common specifications: DN150.

The selection table of accessories of steel tank with arch roof

| nominal capacity (m³) | gauge hatch | light hole | manhole | cleaning holes ordischarge hole | breather valve or vent hole | blow-off pipe |

|---|---|---|---|---|---|---|

| ≤2,000 | 1 | 1 | 1 | 1 | It is approved product and can be ordered according to the maximum blow | 1 |

| 3,000-5,000 | 1 | 2 | 2 | 1 | 1 | |

| 10,000 | 1 | 3 | 3 | 2 | 1 | |

| 20,000-30,000 | 1 | 3 | 4 | 3 | 2 | |

| ≥50,000 | 1 | 3 | 4 | 3 |